HDPE Magic Float Modular Pontoon

Magic Float Enterprises manufactures the world’s most innovative HDPE Magic Float modular pontoon system. Their revolutionary patented interlocking cube design offers a stronger, more stable and robust system than any other modular cuboid pontoon system on the market. Since our inception Work on Water Ltd has grown to become one of the leading UK and European modular pontoon hire companies, able to meet all clients requirements we have the largest hire stocks of Magic Float modular modular pontoons. Our success has been built on our core values of supplying the leading brands of equipment available in our hire supply portfolio, outstanding customer service and our commitment to Health & Safety. The main differences and key advantages of the Magic Float modular pontoon system compared to our competitors are shown below, these advantages put the Magic Float system above all others with superior strength, stability and ease of use.

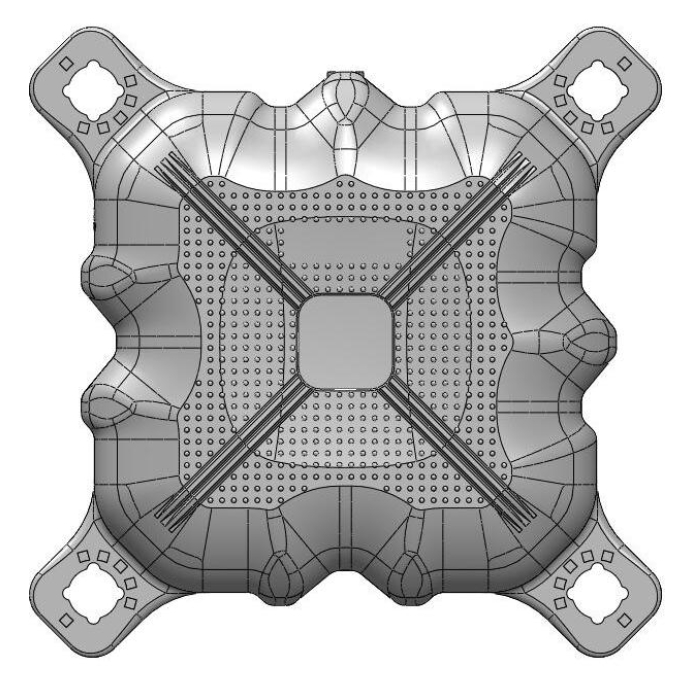

Interlocking Design

The unique interlocking faces of the cubes increases the shear and lateral load bearing capacity by over 60% when compared with an equivalent flat sided cube design. Scientific analysis and mechanical load testing have established the superior load bearing capability of the Magic Float design.

High Strength Connecting Lug

The Magic Float system connecting lugs are 20mm thick with a greater surface join area and designed to give continuous reliable service under tensile loads of up to 2600kgs. By combining the design advantages of stronger connecting lugs and increased lateral load distribution via the interlocking side profiles the Magic Float modular pontoon system has significantly higher load bearing capabilities, platform rigidity and stability than any other system on the market.

Connecting Pin

Our Magic Float system connects together with an extremely durable 8-point locking pin. The connecting pin is pushed down through the connecting lugs and torqued through 45 degree locking the 4 nodules both at the top and bottom into place. Unlike other systems that use a screw threaded connecting pin that can work loose from the live water movement or un-wanted removal by kicking the pin, the Magic Float system connecting pin can only be removed with the correct ‘T’ torque bar requiring reasonable force to torque turn and pull out the pin.

High Quality Materials

Magic Float and its assembly components are manufactured from a superior quality grade industrial strength High-Density Molecular Weight (0,954g/cm3) Polyethylene HD-PE Lupolen 5261Z (BASF) from Germany. This material will not splinter, rot, corrode, is resistant to saltwater, chemicals, acids, hydrocarbons and is 100% UV resistant. Due to its superior grade of HD-PE no leaching from the material will contaminate the water or will be absorbed by it, an important factor when working in environmentally sensitive SSSI waterways

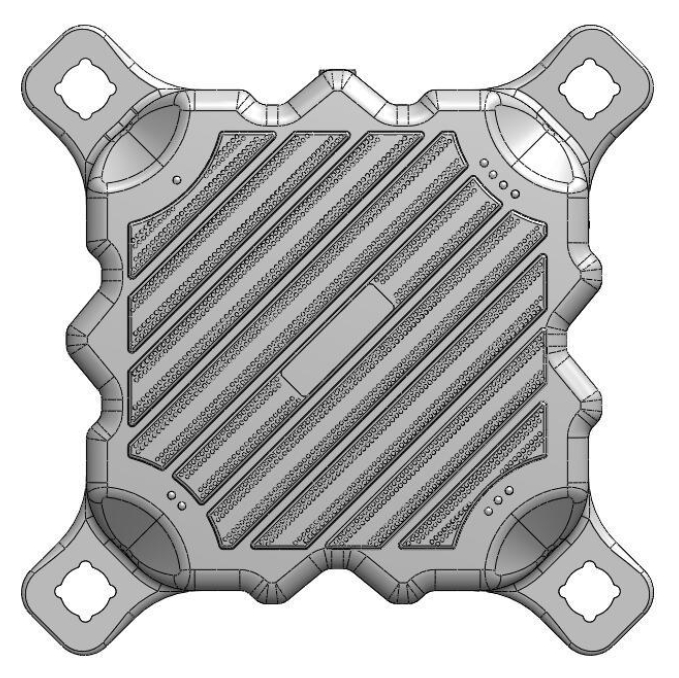

Safer Anti-Slip Surface

Anti-slip is an essential aspect of platforms for safe working on water, Magic Float has a generous water drainage pattern to facilitate good grip in a water environment.